FENGRUI

Since its establishment in 1995, Wenzhou Fengrui Medical Devices Co.Ltd. has been dedicated to the R&D and manufacturing of medicaldiagnostic equipment, specializing in blood pressure monitoring andcardiopulmonary auscultation.As a leading Chinese enterprise infundamental medical diagnostic devices, we boast an annual productioncapacity of 5 million professional sphygmomanometers, with productlines covering household, clinical, and special scenario applicationsacross 8 major series and 126 refined models.

1

- 30 years R&D focus

- 1M professional sphygmomanometers annually

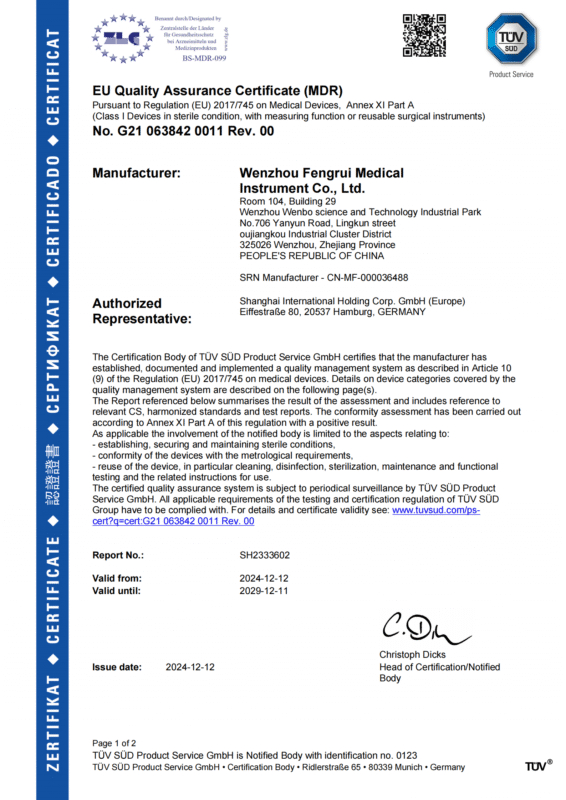

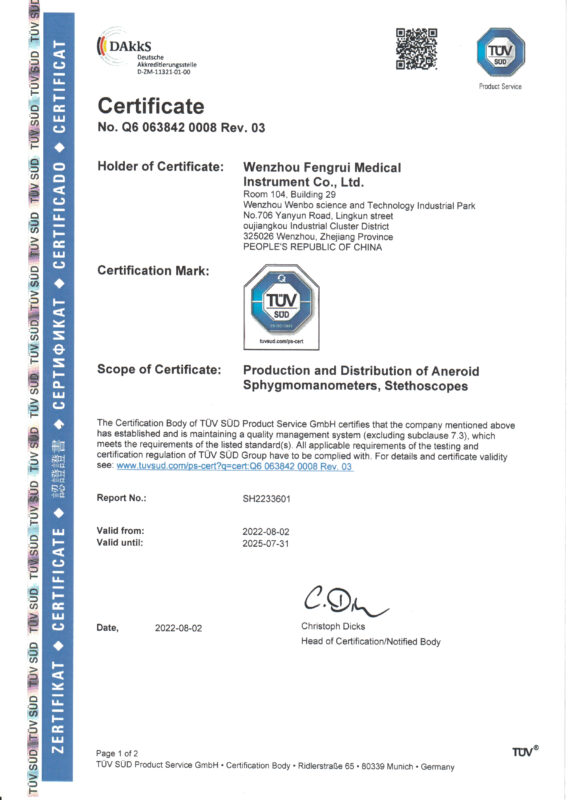

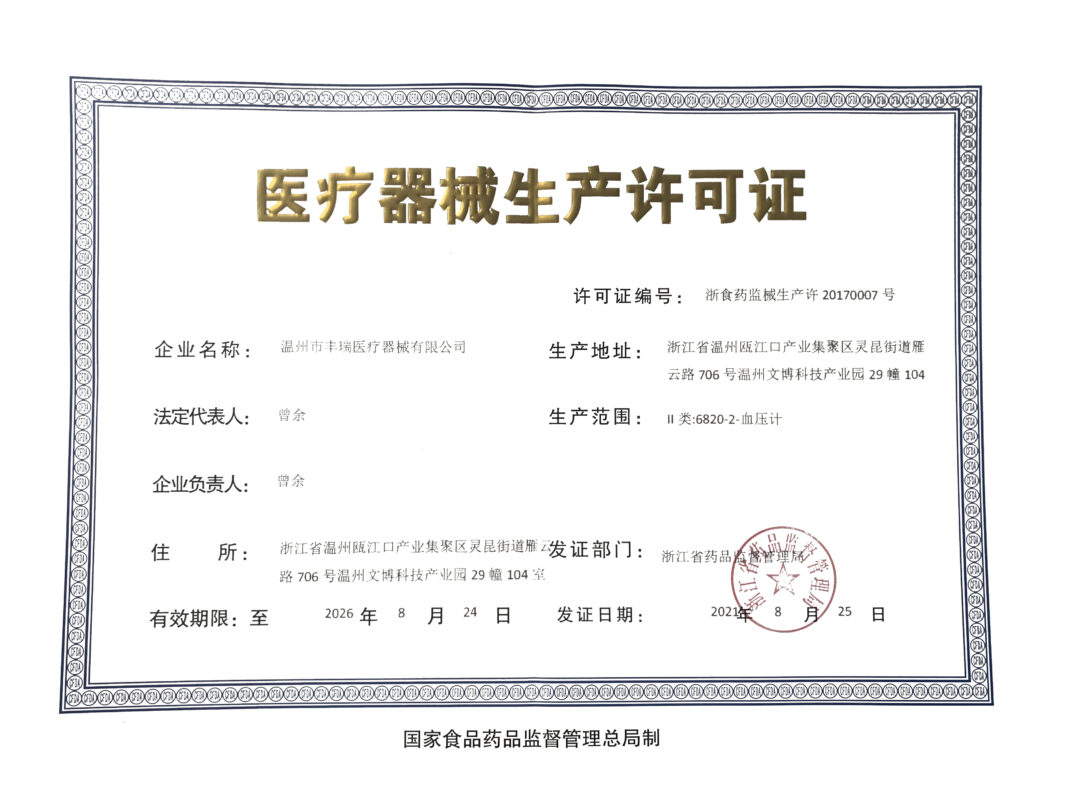

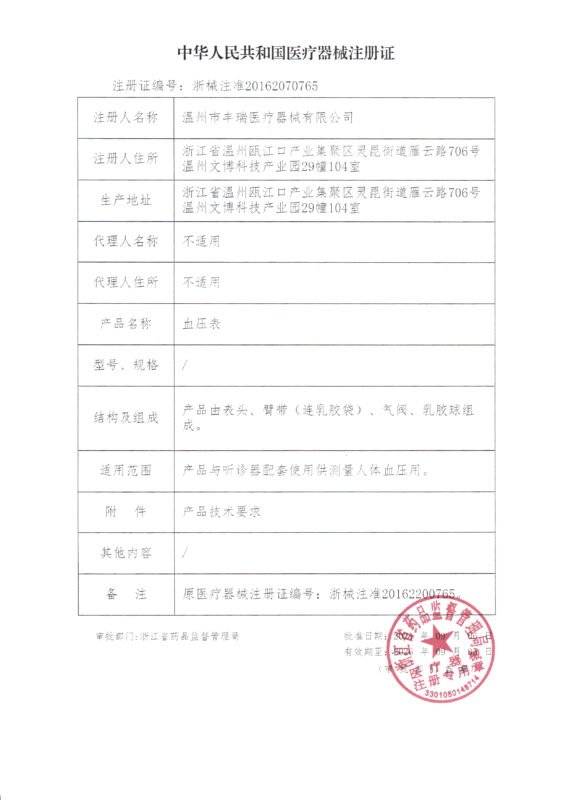

- FuII CE/FDA/MDR/IS013485 certifications

- 0.01mm precision stamping

SPARE PARTS PRODUCTION WORKSHOP

As a certified medical device manufacturer, we are equipped with a100000 level clean workshop and a 1000 square meter intelligent factoryarea, certified by lsO 13485 and MDR quality management system.Integrated intelligent automation production linc and rcal timemonitoring system,using Al driven multi-level quality inspection toachieve vertical control of the entire process from raw materials tosterilization,with a first inspection pass rate of 98,6%

ASSEMBLY WORKSHOP

The assembly workshop maintains a 100,000-class cleanroomenvironment with automated production lines and precision testingequipment, 30 trained technicians work at modular stations under strictGMP standards. Key processes include stethoscope diaphragm pressing.sphygmomanometer valve leakage tests, and dual-operator calibration.All products comply with lSO 13485, with critical stations equipped withHD vision inspection systems ensuring clinical-grade accuracy.meetingCE/FDA certifications

SCHOOL WATCH WORKSHOP

The meter calibration workshop operates in a 10,000-class cleanroomwith temperature/humidity control, specializing in sphygmomanometergauge calibration. Data is digitally archived. Compliant with lSO 13485and JG 270 standards, critical stations feature anti-vibration platforms.Full inspection pass rate reaches 99.97%, meeting CE/FDA clinicalrequirement

RESTRORATION WORKSHOP

The recheck workshop conducts final inspections for sphygmomanometergauges in a 10,000-class cleanroom with temperature-controlled stations.Compliant with lS0 13485 and JG 270 re-inspection protocols, theworkshop operates in anti-maqnetic environments with full batchtraceability,achieving 99.99% pass rate.Supports FDA/CE/MDRcertifications.

PACKAGING WORKSHOP

The packaging workshop implements terminal protection for medicaldevices, utilizing semi-automatic cartoning machines, heat-shrink filmpackaging lines, and laser marking equipment to achieve integratedpackaging of blood pressure monitors with accessories and manuals.Each batch undergoes label verification, seal integrity checks, andanti-counterfeit code activation via vision inspection systems, with 5% ofproducts subjected to unpacking re-inspection. Certified to lSO 15378packaging material standards, the workshop maintains a packagingdefect rate ≤0.02%, complying with CE/FDA/MDSAP globaltransportation requirements.